參考價(jià)格

面議型號

擠出機(jī)品牌

眾鎢自動化產(chǎn)地

福建樣本

暫無規(guī)格外形(長*寬*高):

-膜孔直徑(mm):

-螺桿數(shù):

其他生產(chǎn)能力(kg/h):

-適用物料:

-擠出直徑(mm):

-螺桿直徑(mm):

-工作溫度(℃):

-生產(chǎn)能力:

-自動化程度:

其他功率(kw):

-重量(kg):

-看了擠出機(jī)的用戶又看了

留言詢價(jià)

留言詢價(jià)

虛擬號將在 180 秒后失效

使用微信掃碼撥號

眾鎢擠出機(jī)(連續(xù)擠出成型機(jī)、押出機(jī))采用歐美**先進(jìn)技術(shù)操作簡單,,效率高(是國內(nèi)普通模壓設(shè)備的8-10倍),是目前國內(nèi)先進(jìn)的硬質(zhì)合金實(shí)芯,、單直孔、雙直孔,、雙螺旋,、三螺旋等棒材及板材的生產(chǎn)設(shè)備;同時(shí)也是陶瓷行業(yè)、純鎢,、純鉬,、銅基、鎳基,、鐵基等行業(yè)擠出實(shí)芯棒,、管棒、板材等的生產(chǎn)設(shè)備,。

Zhongwu extruder (continuous extrusion molding machine, extrusion machine) uses most advanced European technology. is easy to manipulate. highly fficient (8-10 times domestic ordinary molding equipments).It is the most advanced domestic production equipment for solid hard alloy, single straight hole, double straight hole, double helix, three screw bar and plate. It is also being used to extrude solid bar, tube, and plate for ceramic, pure lungsten, molybdenum, copper- based, nickel-based, iron-based and other industries.

1,、主要性能說明Main Performance Specification

●眾鎢高效擠出機(jī)生產(chǎn)出的坯料,表面光滑、分布均勻,、無氣泡產(chǎn)生,、有效解決了使用模壓設(shè)備易產(chǎn)生局部密度不均勻問題。

●主機(jī)采用PLc控制,無級調(diào)速,電子調(diào)壓,超壓自動泄壓根據(jù)客戶需要可采用觸摸屏和手動控制面板,。

●料缸可自動翻轉(zhuǎn),裝料方便,容量大,不藏料,易清潔,是螺旋式擠壓機(jī)和普通擠壓機(jī)所不可比擬的,。

●模頭和模套經(jīng)過特殊改良,使換模和換料節(jié)約了大量的時(shí)間,減少了三分之二的勞動強(qiáng)度有效的提高了生產(chǎn)效率。

●根據(jù)生產(chǎn)需要,由光電感應(yīng)設(shè)定棒材特定長度,可自動或手工切斷,感應(yīng)器控制切斷時(shí)間。

●Zhongwu extruder solves the issue of uneven density over the blanks - a common one that is faced by ordinary molding equipments. Blanks produced by Yuchang extruder have a smooth, even and bubble- Iree surlace,。The main engine is Programmable Logic Controlled (PLC). speed variable, whose vollage is rogulated electronically, and pressure aulomatically decompressed. Touch screen and manual control panel can be included upon request.

●Material cylinder can be automaically turned over 10 lcitate loading. It is designed with large capacity.non- possession of material, easiness to clean. It outpaces all spiral extrusion machine and/or general extrusion machines.

●Alter the special improvement on die head and die cases, time used to change moulds and materials arecut substantially to 1/3 ol the original; thus increases the production fficiency.

●Users can set the length of extruded bar, decide to cut them off automatically or manually based on production needs. Sensor will control the time ftor cutting oll, and ensure tha materials are not rubbed or touched.

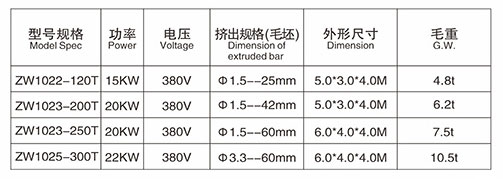

2,、主要技術(shù)參數(shù)Main Technical Parameters

暫無數(shù)據(jù)!

擠出機(jī)的工作原理介紹?

擠出機(jī)的工作原理介紹? 擠出機(jī)的使用方法,?

擠出機(jī)的使用方法,? 擠出機(jī)多少錢一臺,?

擠出機(jī)多少錢一臺,? 擠出機(jī)使用的注意事項(xiàng)

擠出機(jī)使用的注意事項(xiàng) 擠出機(jī)的說明書有嗎?

擠出機(jī)的說明書有嗎? 擠出機(jī)的操作規(guī)程有嗎,?

擠出機(jī)的操作規(guī)程有嗎,? 擠出機(jī)的報(bào)價(jià)含票含運(yùn)費(fèi)嗎,?

擠出機(jī)的報(bào)價(jià)含票含運(yùn)費(fèi)嗎,? 擠出機(jī)有現(xiàn)貨嗎?

擠出機(jī)有現(xiàn)貨嗎? 擠出機(jī)包安裝嗎,?

擠出機(jī)包安裝嗎,? 手機(jī)版:

手機(jī)版: