參考價格

面議型號

GP系列品牌

宜興精新產(chǎn)地

宜興樣本

暫無粉碎程度:

細(xì)粉碎單位能耗:

低產(chǎn)量:

0.5-500Kg/h裝機功率(kw):

0.74-12成品細(xì)度:

0.2-10mm入料粒度(mm):

<150工作原理:

輥壓碾磨 留言詢價

留言詢價 電話詢價

電話詢價

虛擬號將在 180 秒后失效

使用微信掃碼撥號

GP系列·全陶瓷無污染輥式破碎機

GP series · All ceramics contamination-free roller crusher

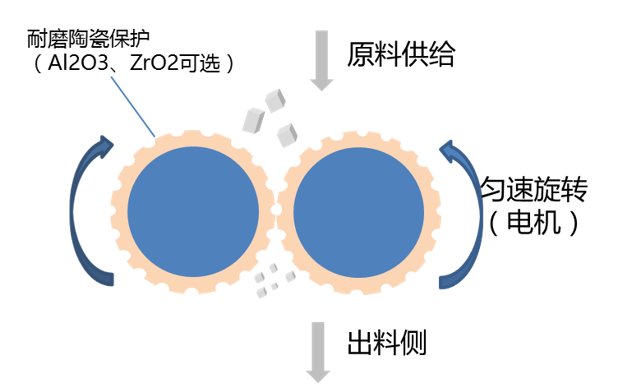

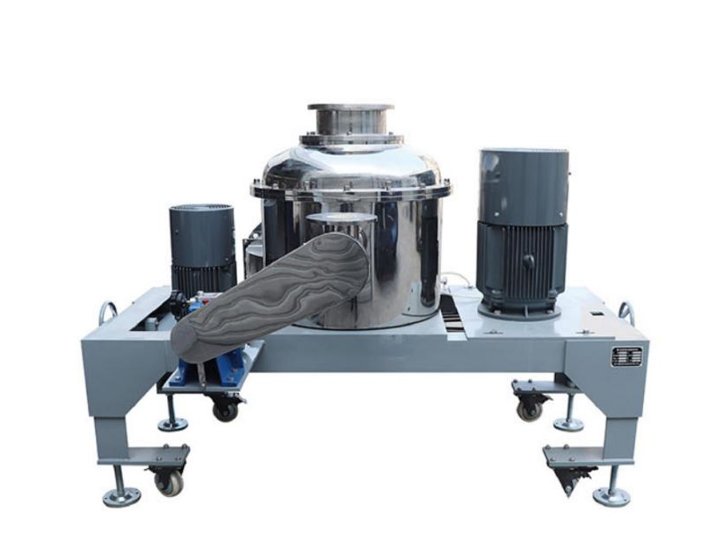

工作原理:

小塊狀或顆粒狀物料被投入破碎腔后,受到來自兩輥相向轉(zhuǎn)動產(chǎn)生的擠壓和咬合,,從而被破碎通過兩輥之間的間隙出料,。

working principle:

After being put into the crushing cavity, small or granular materials are crushed and bitten by the opposite rotation of the two rollers, so that they are crushed and discharged through the gap between the two rollers.

設(shè)備特點:

適用于脆性物料的粗破碎,應(yīng)用于鋰電池材料,、電子材料,、高純化工材料,、高新陶瓷材料領(lǐng)域。

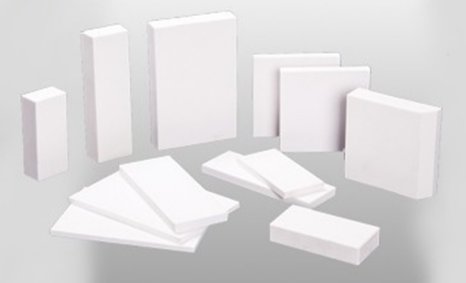

沖擊磨損部位全部耐磨陶瓷防護(hù),,從而滿足多數(shù)高新材料避免金屬雜質(zhì)污染要求,,關(guān)鍵部位包括兩支瓷輥等。

可根據(jù)物料性質(zhì)和客戶要求,,對瓷輥進(jìn)行抽槽處理以增加咬合力,,也可以對接為雙層對輥從而接受較為大塊的原料破碎;可提供全密閉破碎形式,,避免粉塵外泄且可通入惰性氣體保護(hù)破碎,。

1. It is suitable for the coarse crushing of brittle materials, and is used in the fields of lithium battery materials, electronic materials, high-purity engineering materials, and high-tech ceramic materials.

2. All impact wear parts are protected by wear-resistant ceramics to meet the requirements of most high-tech materials to avoid the contamination of metal impurities. The key parts include two ceramic rollers.

3. According to the material properties and customer requirements, the ceramic roller can be grooved to increase the bite force, or it can be combined as a double-layer roller to accept the crushing of larger pieces of raw materials; it can provide a fully enclosed crushing form to avoid dust leakage and can pass inert gas to protect the crushing.

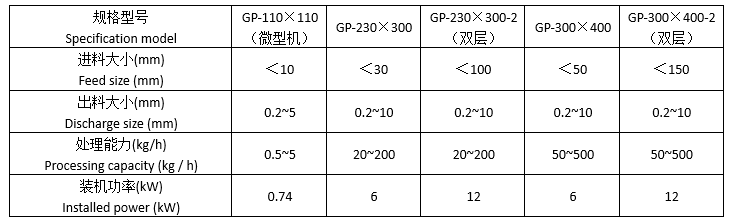

技術(shù)參數(shù)表(Technical Data Sheet):

注:具體配置及處理效果需根據(jù)物料性質(zhì)與加工要求確認(rèn),可與我司工程師溝通或來料試驗,。

Note: The specific configuration and processing effect need to be confirmed according to the material properties and processing requirements, and you can communicate with our engineers or come to do materials processing test first.

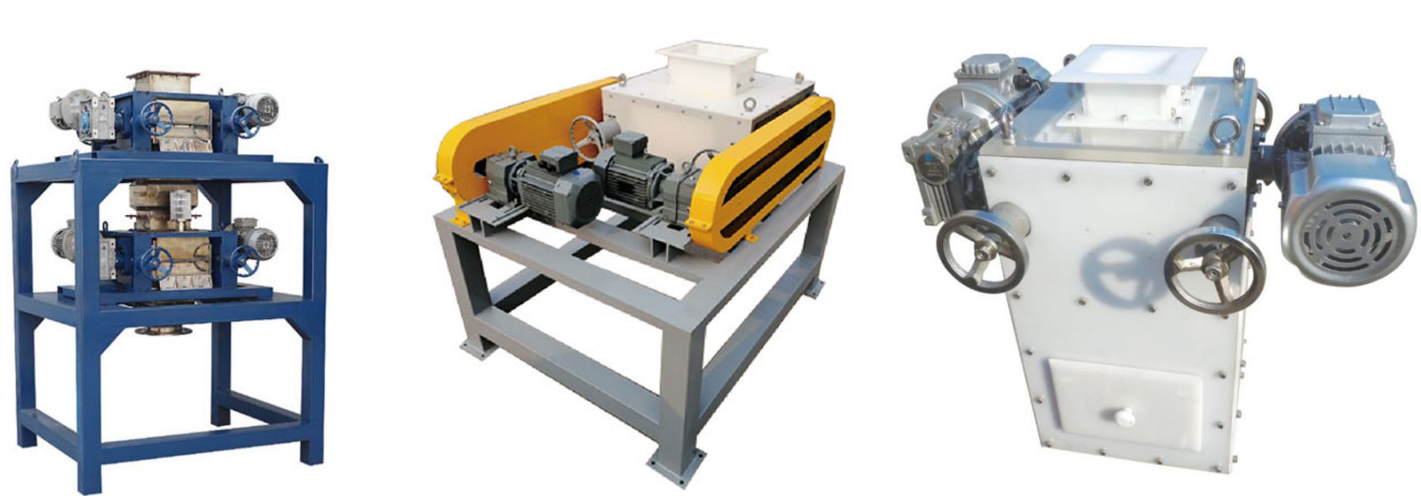

實物圖片(Physical picture):

GP-230*300(中型機) GP-230*300(皮帶式) 微型機

GP-230*300(中型機)(Medium model) GP-230*300(中型機)(Belt type) Micromodel

相關(guān)**: 全陶瓷齒輪輥式粉碎機(實用新型ZL 201621158532.9)

全陶瓷齒輪輥式粉碎機(發(fā)明ZL 201610934322.2)

一種帶均勻?qū)Я瞎δ艿娜沾奢伿狡扑闄C(實用新型 ZL 201821570126.2)

暫無數(shù)據(jù),!

在半導(dǎo)體,、光電材料及醫(yī)藥等高精度尖端領(lǐng)域,原材料的“無污染”純凈度是推動技術(shù)進(jìn)步,,確保產(chǎn)品安全,、性能卓越的關(guān)鍵要素。特別是在半導(dǎo)體制造領(lǐng)域,,雜質(zhì)可以影響半導(dǎo)體的電導(dǎo)率,,導(dǎo)致性能降低或者失效。在這些雜質(zhì)

一直以來“鐵”質(zhì)材料是一種常見的耐磨材料,,尤其像錳鋼,、白口鑄鐵、合金鋼等是幾種廣泛應(yīng)用的耐磨材料,。但這些材料存在一定的弊端,,例如奧氏體錳鋼具有良好的韌性,,但是加工較困難,;普通白口鑄鐵和低合金白口鑄鐵有

超細(xì)粉碎技術(shù)是為適應(yīng)現(xiàn)代技術(shù)要求而發(fā)展起來的一種新的粉碎技術(shù),能把原材料加工成微米甚至納米級的微粉,,由于顆粒向微細(xì)化發(fā)展,,導(dǎo)致物料表面積和孔隙率大幅度的增加,因此超微粉體具有獨特的物理和化學(xué)性質(zhì),,如良

冬天氣溫低,,柴油和水都比較容易凍著,,在啟動機械時就比較困難,同時零件磨損和燃油消耗量顯著增加,,所以在入冬之前必須采取相應(yīng)的保養(yǎng)措施,,對破碎機做徹底的檢查、保養(yǎng),,確保工程機械安全過冬,。在冬季保養(yǎng)粉碎機(

全陶瓷無污染輥式破碎機的工作原理介紹?

全陶瓷無污染輥式破碎機的工作原理介紹? 全陶瓷無污染輥式破碎機的使用方法,?

全陶瓷無污染輥式破碎機的使用方法,? 全陶瓷無污染輥式破碎機多少錢一臺,?

全陶瓷無污染輥式破碎機多少錢一臺,? 全陶瓷無污染輥式破碎機使用的注意事項

全陶瓷無污染輥式破碎機使用的注意事項 全陶瓷無污染輥式破碎機的說明書有嗎?

全陶瓷無污染輥式破碎機的說明書有嗎? 全陶瓷無污染輥式破碎機的操作規(guī)程有嗎,?

全陶瓷無污染輥式破碎機的操作規(guī)程有嗎,? 全陶瓷無污染輥式破碎機的報價含票含運費嗎,?

全陶瓷無污染輥式破碎機的報價含票含運費嗎,? 全陶瓷無污染輥式破碎機有現(xiàn)貨嗎?

全陶瓷無污染輥式破碎機有現(xiàn)貨嗎? 全陶瓷無污染輥式破碎機包安裝嗎,?

全陶瓷無污染輥式破碎機包安裝嗎,? 手機版:

手機版: