參考價(jià)格

面議型號(hào)

SVU品牌

Donaldson產(chǎn)地

無(wú)錫樣本

暫無(wú)收灰方式:

XX進(jìn)風(fēng)方式:

XX排放濃度:

XX阻力損耗:

XX脫硫率:

XX風(fēng)量:

XX使用溫度:

XX除塵效率:

XX工作原理:

濾筒看了PowerCore SVU除塵器的用戶(hù)又看了

留言詢(xún)價(jià)

留言詢(xún)價(jià) 電話詢(xún)價(jià)

電話詢(xún)價(jià)

虛擬號(hào)將在 180 秒后失效

使用微信掃碼撥號(hào)

The Donaldson SVU series brings the performance and convenience of the PowerCore? technology to the silo venting market. Built to withstand severe weather conditions, the SVU series is specially designed to vent pneumatically filled storage silos during truck unloading operation.

The Silo Venting Unit will satisfy the need not only for efficiency and reduced maintenance, but also for convenience and workplace safety. You can’t always avoid having your maintenance workers climbing and working on high height silos, but you can control how convenient and safe it is.

Time-consuming and often very dirty maintenance processes, frequently under precarious working conditions, are a thing of the past when using the PowerCore SVU.

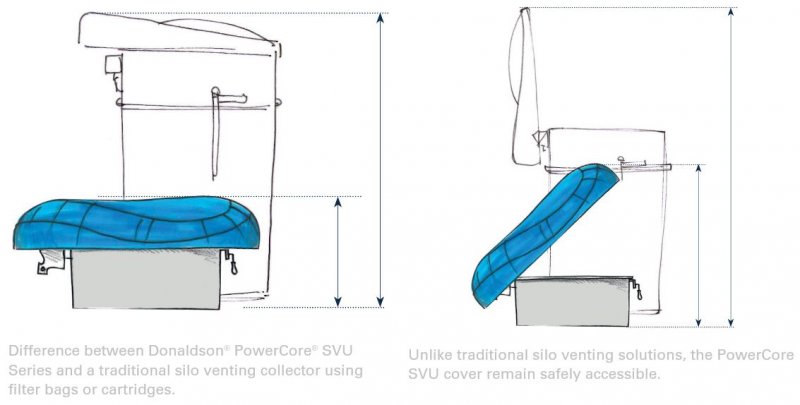

Up to 54% shorter compared to conventional silo dust filters.

High quality Stainless steel body with weather protective hood.

No tooling required, no losable parts, and low height of just 532 mm / 21 in.

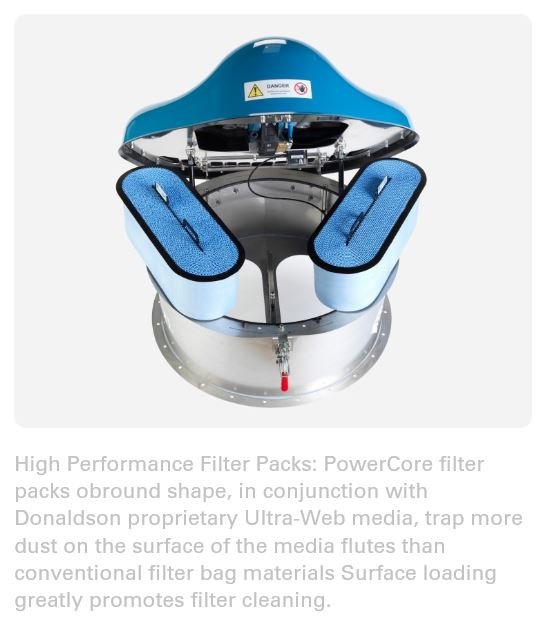

Pulse Jet cleaning combined with PowerCore technology means extended filter life and service intervals.

The SVU is up to 54% shorter than traditional silo venting collectors; its compact and low height design provides easy and safe access to the filter packs. With the Silo Venting Unit, you can save space, reduce maintenance requirements and hazards generated by changing long and dirty filter bags or cartridges on a silo top. While up to 6 bag filters or cartridges have to be moved up and down on conventional silo venting solutions, the SVU only needs 2 lightweight and compact filter packs; changing the PowerCore filter packs can be done easily and safely by just one person with no tools or losable part, in no time.

The performance, reliability, and ergonomy of the SVU is derived from a combination of advanced filtration technology, unique form factors and high performance reverse jet cleaning to ensure effective dust release and a continuous level of operation for longer. Fewer filters, better cleaning, and shorter maintenance leads to major cost savings over the life of the collector.

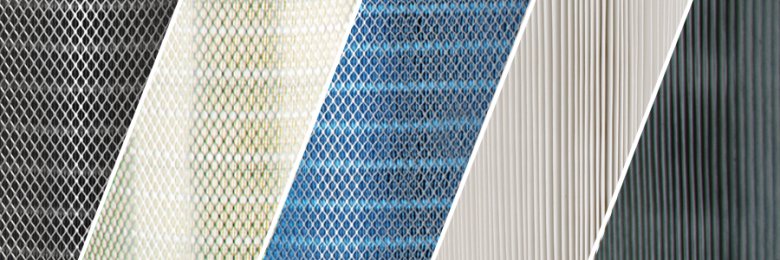

At the core of the SVU unique design is PowerCore, the most innovative filtration technology from Donaldson integral to the dramatic downsizing of the PowerCore SVU series. An entirely new approach to dust collectors, the PowerCore filter pack is small, lightweight, and easily handled by one person. Donaldson’s PowerCore technology combined to our well-proven Ultra-Web? advanced fine fiber technology allows more effective filter area to be packaged in a smaller space.

Pneumatic Silo Venting applications typically requiring up to 6 filter bags or cartridges (24 m2/ 258 ft2 ) in the past now only needs 2 PowerCore compact filter packs. With more media packed into a smaller space and a simplified airflow path, PowerCore filter packs provide high performance with a low pressure drop.

暫無(wú)數(shù)據(jù),!

DCE100系列除塵器

DCE100系列除塵器  一體式高負(fù)壓除塵器

一體式高負(fù)壓除塵器  MBT除塵器

MBT除塵器  UNIMASTER除塵器

UNIMASTER除塵器  褶式濾筒

褶式濾筒  傳統(tǒng)濾袋

傳統(tǒng)濾袋  濾筒總樣本

濾筒總樣本  除塵器總樣本

除塵器總樣本  Dalamatic袋式除塵器

Dalamatic袋式除塵器  DFE除塵器

DFE除塵器

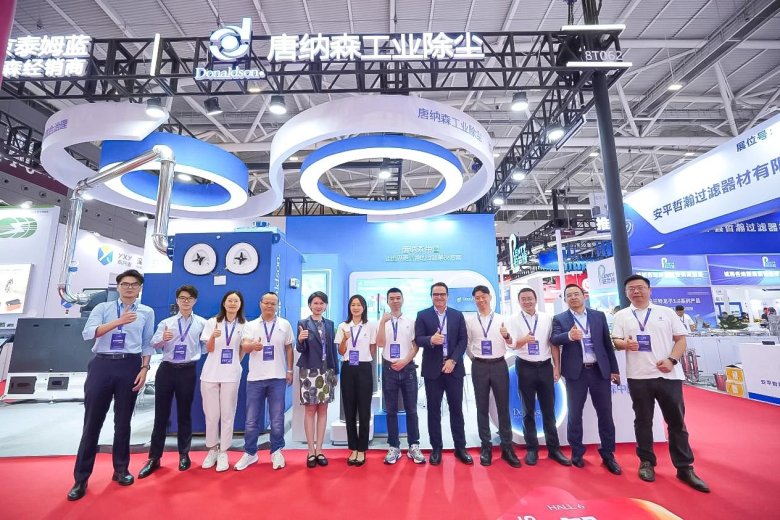

2025年5月15-17日,,在全球矚目的CIBF2025展會(huì)上,,全球除塵領(lǐng)域百年企業(yè)唐納森攜旗下專(zhuān)為鋰電行業(yè)打造的產(chǎn)品及解決方案驚艷亮相。圖:唐納森展位走進(jìn)唐納森展位,,一臺(tái)通過(guò)國(guó)際CE和ATEX雙認(rèn)證

高品質(zhì)過(guò)濾器能幫助礦企在 新能源賽道上穩(wěn)步前行嗎,? 認(rèn)知迭代現(xiàn)代礦山對(duì)于重型采礦設(shè)備的出勤率和使用壽命有著嚴(yán)苛的要求,,這使得許多企業(yè)對(duì)于采購(gòu)決策及設(shè)備維保進(jìn)行著二次審視。尤其是在新

2025年5月15日,第十七屆中國(guó)國(guó)際電池技術(shù)展覽會(huì)(CIBF2025)在深圳國(guó)際會(huì)展中心盛大開(kāi)幕,。作為知名的工業(yè)除塵解決方案提供商,,唐納森攜最新除塵過(guò)濾產(chǎn)品亮相展會(huì),吸引了眾多客戶(hù)和行業(yè)專(zhuān)家的目光,,

專(zhuān)注過(guò)濾領(lǐng)域超百年,,唐納森研發(fā)出了針對(duì)不同應(yīng)用工況的過(guò)濾基材,可滿足不同工況濕度,、溫度,、粉塵粒徑和化學(xué)特性的除塵需求。面對(duì)唐納森多樣化的濾筒濾材選擇,,您可能不清楚哪一款濾筒才能滿足您的生產(chǎn)工藝的除塵需

您的除塵器運(yùn)行時(shí)是否出現(xiàn)過(guò)風(fēng)機(jī)劇烈震動(dòng),、運(yùn)行噪聲逐步變大的情況?這不是一個(gè)小問(wèn)題,,應(yīng)該及時(shí)引起重視,。風(fēng)機(jī)震動(dòng)或噪聲大可能是安裝出錯(cuò),也有可能是風(fēng)機(jī)軸承等轉(zhuǎn)動(dòng)部件維護(hù)不當(dāng),。本文將逐一分析,,并為您提供解決

在工業(yè)生產(chǎn)中,除塵濾芯經(jīng)常用于處理鑄造,、噴涂,、冶金、炭黑等工藝產(chǎn)生的廢氣,,攔截?zé)煔庵袛y帶的微小顆粒物粉塵,,以達(dá)到環(huán)保要求、優(yōu)化生產(chǎn)成本,、保障生產(chǎn)環(huán)境的目的,。濾芯是除塵器的重要組成部分,安裝在除塵器內(nèi)部

PowerCore SVU除塵器的工作原理介紹,?

PowerCore SVU除塵器的工作原理介紹,? PowerCore SVU除塵器的使用方法,?

PowerCore SVU除塵器的使用方法,? PowerCore SVU除塵器多少錢(qián)一臺(tái)?

PowerCore SVU除塵器多少錢(qián)一臺(tái)? PowerCore SVU除塵器使用的注意事項(xiàng)

PowerCore SVU除塵器使用的注意事項(xiàng) PowerCore SVU除塵器的說(shuō)明書(shū)有嗎,?

PowerCore SVU除塵器的說(shuō)明書(shū)有嗎,? PowerCore SVU除塵器的操作規(guī)程有嗎,?

PowerCore SVU除塵器的操作規(guī)程有嗎,? PowerCore SVU除塵器的報(bào)價(jià)含票含運(yùn)費(fèi)嗎?

PowerCore SVU除塵器的報(bào)價(jià)含票含運(yùn)費(fèi)嗎? PowerCore SVU除塵器有現(xiàn)貨嗎,?

PowerCore SVU除塵器有現(xiàn)貨嗎,? PowerCore SVU除塵器包安裝嗎,?

PowerCore SVU除塵器包安裝嗎,? 手機(jī)版:

手機(jī)版: