看了全自動微通道反應機組的用戶又看了

留言詢價

留言詢價

虛擬號將在 180 秒后失效

使用微信掃碼撥號

概述/General Introduction

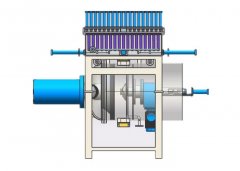

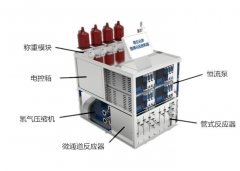

全自動微通道反應機組是由控制系統(tǒng),、配料系統(tǒng),、進料系統(tǒng)、微通道反應系統(tǒng),、后處理系統(tǒng)四五大部分組成,,通過高壓恒流泵推動下進行反復撞擊的原理進行反應,有效地提成了收得率,,減少了副反應的發(fā)生,,縮短了反應時間,消除了反應過程中的放大效應,。實現(xiàn)化學反應全智能,,全自動生產(chǎn)。

Automatic FRAPP’S Flow-Reactor unit is composed of control system, feeding system ,micro-channel reaction system, post-processing system .Effectively improve the yield ,reduce the occurrence of side effects ,shorten the reaction time, eliminate the amplification effect of the reaction .It can Achieve fully automatic, all-intelligent chemical reaction.

適應磺化,、重氮化,、氧化、硝化等高放熱,、高污染,,劇毒反應。

Applicable to sulfonation, diazotization ,oxidation, nitration and other high exothermic ,high pollution , and highly toxic reaction

優(yōu)勢/Advantage

全自動微通道反應機組的特點和優(yōu)勢: Characteristics and Advantages of fully Automatic Micro-channel Reactor | 連續(xù),、密閉,,瞬間反應物料量小,可精確控制反應條件自動控制程度 Continuous, closed ,small instantaneous reaction material ,can be precisely controlled 高精度,,高壓力,,更安全,更環(huán)保,,更高效,,傳熱傳質(zhì)效率高 High precision ,high pressure ,safer pressure, safer ,more environmentally friend, more efficient ,high heat transfer mass transfer efficiency | 降低能耗的同時提高產(chǎn)物的選擇性,保持環(huán)境的清潔,,減少污染 Reduce energy consumption, improve the selectivity of products, keep the environment clean and reduce pollution 滿足客戶GMP要求 Meet customer GMP requirements |

暫無數(shù)據(jù),!

全自動微通道反應機組的工作原理介紹,?

全自動微通道反應機組的工作原理介紹,? 全自動微通道反應機組的使用方法?

全自動微通道反應機組的使用方法? 全自動微通道反應機組多少錢一臺,?

全自動微通道反應機組多少錢一臺,? 全自動微通道反應機組使用的注意事項

全自動微通道反應機組使用的注意事項 全自動微通道反應機組的說明書有嗎,?

全自動微通道反應機組的說明書有嗎,? 全自動微通道反應機組的操作規(guī)程有嗎?

全自動微通道反應機組的操作規(guī)程有嗎? 全自動微通道反應機組的報價含票含運費嗎,?

全自動微通道反應機組的報價含票含運費嗎,? 全自動微通道反應機組有現(xiàn)貨嗎,?

全自動微通道反應機組有現(xiàn)貨嗎,? 全自動微通道反應機組包安裝嗎?

全自動微通道反應機組包安裝嗎? 手機版:

手機版: